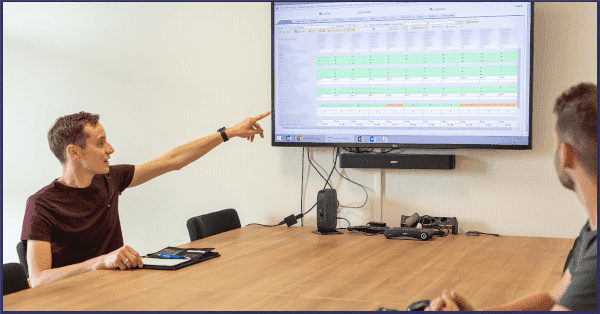

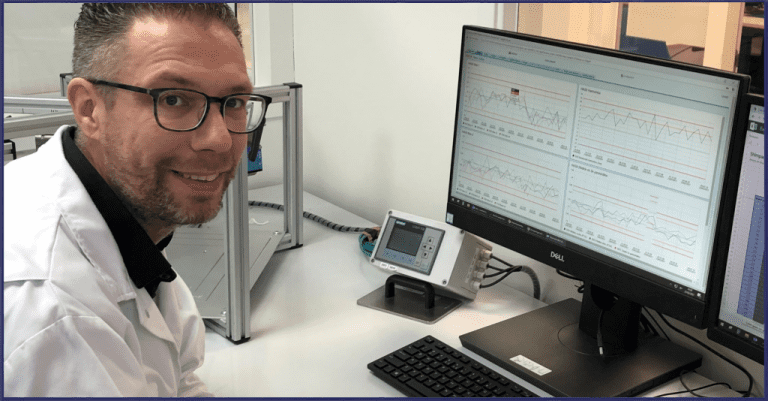

Turning Data Into Actionable Insights

In conversations with Plant Managers and Production Leaders in the Food Industry, it comes up again and again: everyone wants more control over the process, but the proliferation of Dashboards and Excel sheets does not seem to be the right approach.