Royal A-ware’s mozzarella/cream factory optimal digital

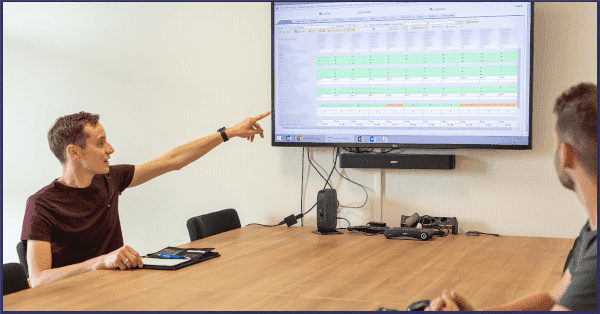

Royal A-ware looks back on a successful start-up of their new mozzarella/cream plant. This was due to very thorough preparations, also in the domain of digitalization.

“We have set the bar high, and are still reaping the benefits of this every day,” said Ype de Jong, site manager of the brand new factory.