Barcode scanning in (Food) Factories

Barcode scanning in (Food) Factories

Barcode scanning in the factory proves to be a fantastic solution for reliable production information

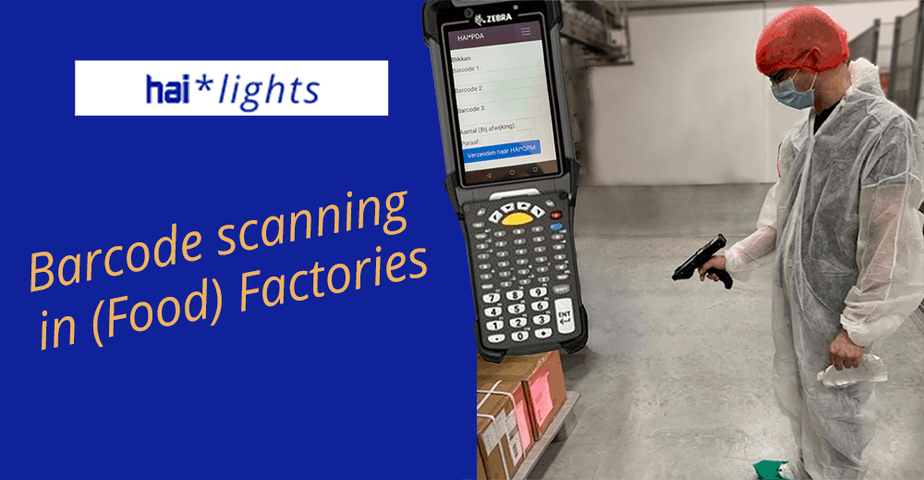

The photo is not about a box being held at gunpoint. What is happening is the smart scanning of barcodes on the box. In the past, operators had to manually record all codes on lists. That was time-consuming with a high risk of errors. In this factory, they are glad they made the step to scanning: “The scanning system was ready for use within a few weeks, and the operators could quickly get to grips with it”. Says the engineer who supervised the introduction of the scanning system.

He says: “Operators simply scan the codes and the software immediately stores all the information in a central cloud database. This way, operators work faster and more accurately, and they are relieved of time-consuming paper registrations. And – equally important – you prevent errors and get a better overview of exactly what is happening in production.”

ERP-systems do not record accurately enough

Surprisingly, the barcode scanning application is not just to register raw materials or finished products as part of the batch postings. After all, (food) manufacturers register much more during production. This is necessary because for each process step and for each quality control test you must record which production order, which article code and which batch you are processing. Indeed, for each batch produced, you have to be able to trace back in detail the origin and production date of the raw materials, ingredients and packaging materials used. An ERP system for business administration often records information of the batch as a whole. But it doesn’t allow you to keep track of this accurately enough. The detailed information about each different process step and their time-stamps are missing.

Think, for example, of food safety: suppose a supplier warns you that there is a problem with a batch of ingredient X. Then you want to know exactly in which products (and parts of batches) this batch of ingredient X was processed. And to which customers it was shipped. Or you get a complaint on your finished product. Then you want to know everything about the production batch to which the complaint relates.

Stacks of forms

As a result, operators have to perform a whole series of registrations at each step in the production process. No wonder, then, that many manufacturers have stacks of forms to fill every day with batch numbers, article codes, a production date, best-before date, etc.

This is not limited to the precise registration of ingredients and finished products. It is also about registering other things. For example, registering which operator is on the line, which analyses an external lab needs to perform or the exact time a dose was added. You can now easily scan all these things instead of keeping track of them manually.

Convenient scanning and reporting

Thus, for each workstation there is customized HAI*PDA software for scanning the barcodes and QR codes. So it is customized for each department: for example, the department where operators add the ingredients. Or the lab where lab technicians prepare the samples for shipment ot the external lab. Or the department where the packaging materials are prepared.

Scanning is one thing: but you also want to be able to look up and report the data easily.

The HAI*PDA software writes the data in real-time to the central cloud database. That central cloud database is linked to real-time dashboards and reports. These real-time dashboards make all scaned information available to operators and other factory and quality personnel. And they can easily look up all historical information.

“Nobody wants to go back to the forms of the past,” laughs the team leader. “It’s important that I can now find out exactly what happened in production with one mouse-click. And that I can rely on it,” adds the Quality Manager.

Want to know more?

Read here about the successful use of barcode scanning in the laboratory of a dairy factory.

The scanned information is part of a complete information system about production and quality. Read more about all information that factories include in the HAI software. And how they use it to their benefit.

Get inspired

Interested in more best practices of smart use of factory data, especially in the Food Industry?

Get inspired by successes of others when it comes to OEE, quality, positive release, golden batch, CIP-cleaning, operator support, factory data anaytics, in-line measurements, factory dashboards… and much more.

Do not miss it and follow us on LinkedIn: