The logsheets are a unique part of the software, cherished by users, and brilliant in its capabilities.

The logsheets are the screens where end-users view their information. What makes them special is that the logsheets combine a wide range of functionalities on a single screen, a.o. an Early Warning System to prevent out-of-spec situations.

In the logsheets, we can see:

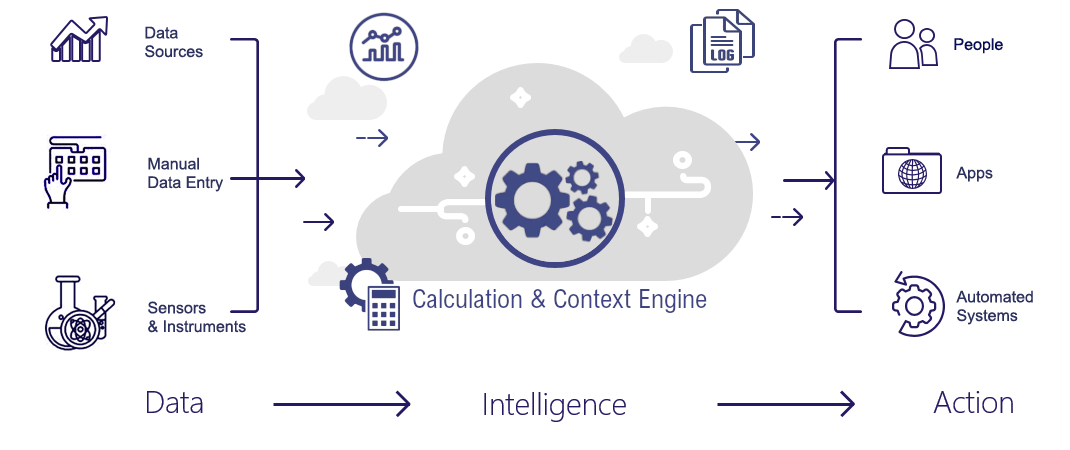

- Real-time data visualization & trending

- Automatic data collection & Manual data entry

- Data in context

- Compliance with standards

- Raw Data & Calculated Data

- A mix of different types of data

- Powerful filtering in historical data

- Statistical Process Control (SPC)

- A statistical model

As a result, manufacturers can unlock all data from their primary production process (process data, quality, utilities) and offer it in a directly usable format in the form of logsheets. Custom-designed logsheets can be created for:

- Every workstation in production or the lab.

- Specific roles (technologist, quality officer, manager).

- Specific purposes (energy monitoring, water consumption, mass balance, yield calculation, microbiology, etc.).

Key users without IT knowledge can configure logsheets themselves after a short training, using a simple configuration menu. Therefore, no IT knowledge is required!

Depending on the size and diversity of a production site, there can be anywhere from twenty to over a hundred logsheets. Every data point from the database can be found in one or more logsheets.

In HAI, the automatic data collection setup automatically leads to visualization in a logsheet. This means that all collected data is always visible in real-time!