Use Case: Variable Changeover times (OEE)

Changeover times often depend heavily on the previous product and the one being set up next.

To guide your teams effectively, you need realistic changeover standards. This requires linking live planning data with operational standards. In this case study, Tom Mentink shows the impact that combining data, technological knowledge and process control can have.

In packaging manufacturing, the complexity of large industrial printing lines with all possible products is already overwhelming. On top of that, in this particular case, a daily cleaning cycle had to be factored in.

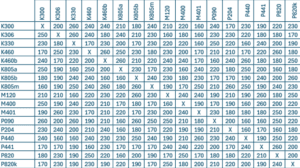

By combining process knowledge and data, we identified five key factors that determine changeover duration.

Integrating planning software with production control now gives the team a realistic changeover target, which is discussed on the KPI board.

Improvements in any of the five factors can be immediately calculated for all changeovers and incorporated into the PCS.

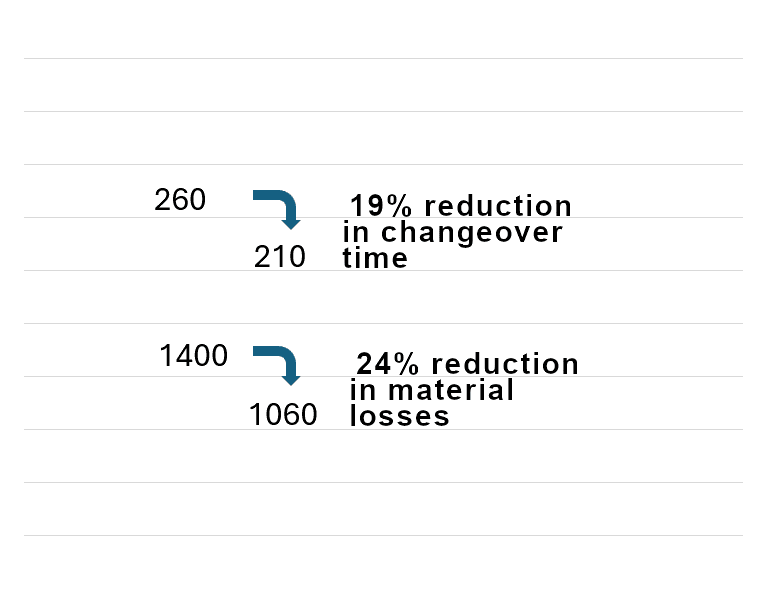

Results: Changeover improvements significantly increased print line capacity

With so many different changeovers, comparing shift performance was challenging. But with realistic targets, this became possible.

The discussions sparked by this data led to optimized work instructions that were accepted by all teams.

Project executed by Tom Mentink