Oliehoorn Factory Data in HAI: Sensaucetional Taste, Smartly Made

How Smart Logsheets Drive Peak Performance in Production

Oliehoorn Factory Data in HAI: Sensaucetional Taste, Smartly Made

How Smart Logsheets Drive Peak Performance in Production

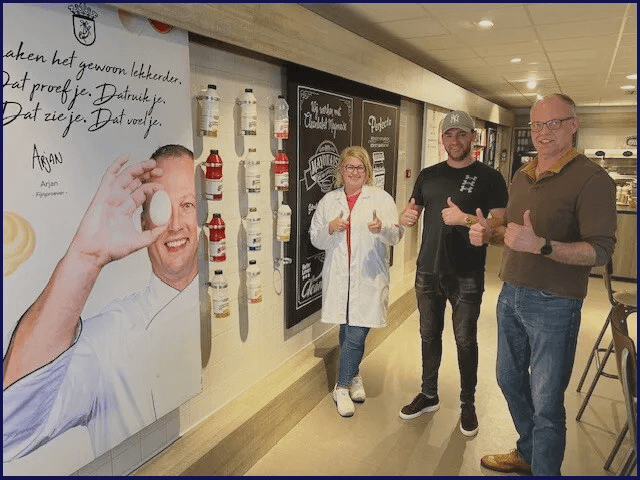

Oliehoorn has embarked on the rollout of the HAI Data Platform in the Azure Cloud—an exciting step that reflects the company’s bold ambitions for both sustainability and growth.

The Dutch family-owned business—famous for its fries sauce, curry, mayonnaise, and ketchup—is building the future of food production with smarter processes and sharper insights.

With the HAI Data Platform, Oliehoorn is equipping its teams with real-time data and powerful digital tools to optimize every step of the production process. The result? More control, less waste, and better decisions—all driving consistent quality and efficiency.

Sustainability Meets Smart Innovation

At Oliehoorn, sustainability isn’t a side project—it’s at the heart of the business. “As a family company, we focus on long-term value and invest continuously in the future of our business,” says Managing Director Arjan Dijk.“That means working with sustainable ingredients, low-impact packaging, and building honest partnerships. We’re driven, growing fast, and committed to doing it responsibly.”

Their recent B Corp certification is a testament to this commitment. And the new, gas-free sauce factory currently being built is a clear next step: targeting a 40% reduction in energy use compared to the current facility, it’s set to become the most sustainable sauce factory in Europe.

Smart Growth, Guided by Data

To ensure this rapid growth is managed efficiently, Director of Operations Atso de Jong brought together a dedicated project team and introduced HAI to the organization. “With the HAI Data Platform, we can confidently scale up while staying aligned with our sustainability goals,” he explains.

Real-Time Insights, Real-World Impact

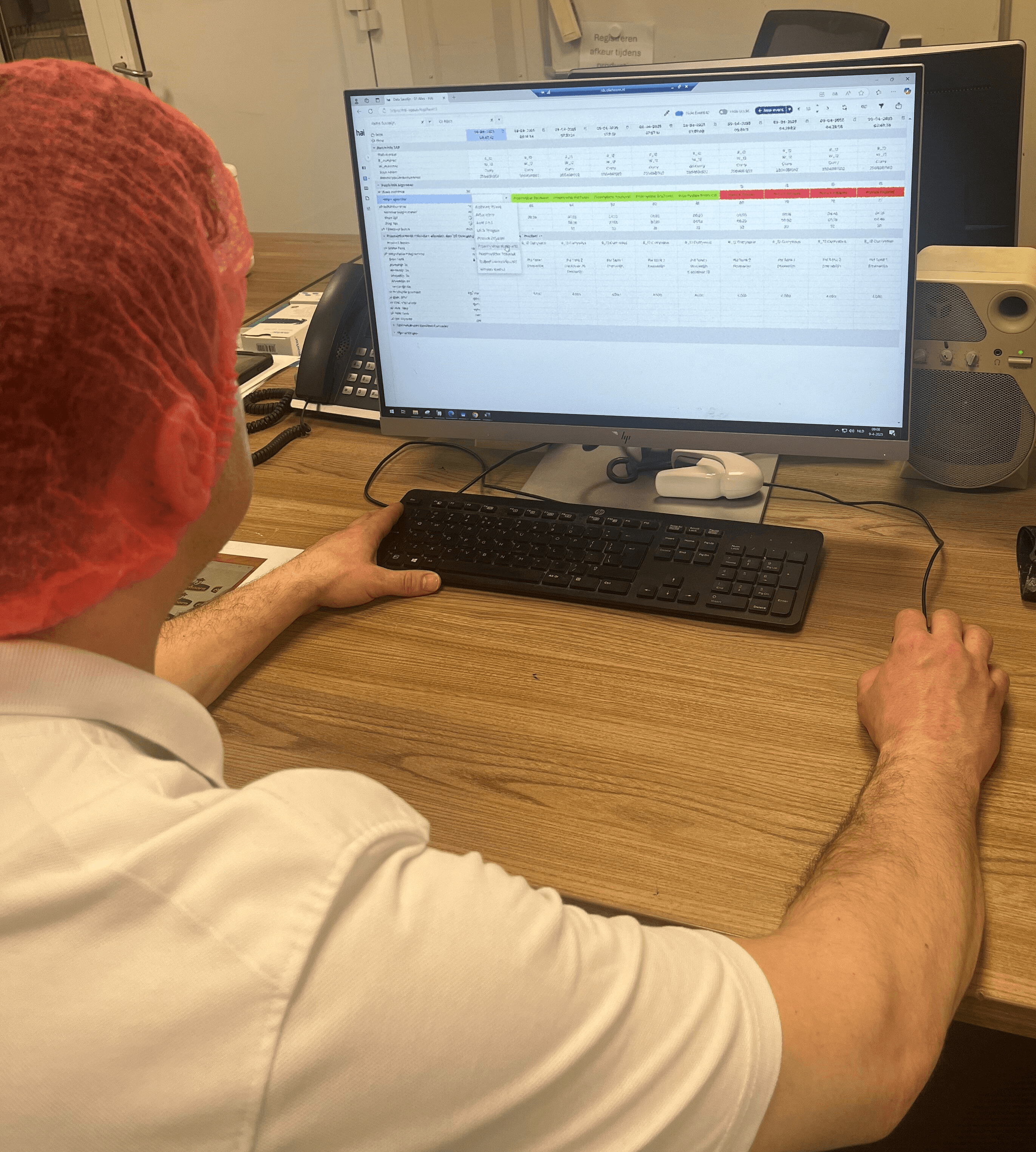

We asked two team members how this platform will make a difference on the floor—Anna Lewandowska from Production and Mick Manshande from Quality.

Anna:

“Our production team is genuinely excited. With HAI, we’ll be able to perform real-time quality checks, catch deviations early, and produce more consistent quality. That means more waste reduction and greater customer satisfaction.”

Mick adds:

“Traceability, fast access to data, and early detection of issues are critical for us. HAI enables us to log everything digitally—from pasteurization and cooling temperatures to RPMs of our emulsification systems and visco rotor, and pH levels. That’s a huge advantage for audits and complaint investigations.”

Doing More with Less

Sustainability isn’t just about green energy and recyclable packaging. It’s about making the most of every resource—with a lean, motivated team that delivers maximum quality and output with minimal waste. And that’s exactly where the HAI Cloud Platform will make a lasting difference.

A Phased Approach with Big Potential

Even though the enthusiasm is high, Oliehoorn has opted for a phased rollout—starting with two digital logsheets where operators will enter key process controls. These will be automatically linked to production order data from the SAP system.

Next, more manual checks will follow, along with automatic data collection from process control systems, scales, and inline quality sensors.

Laat je inspireren

Laat je inspireren door het succes van anderen op het gebied van de digitale transformatie, data-gedreven werken en slim gebruik van data (science) in de fabriek. Denk ook aan toepassingen op het gebied van OEE, kwaliteit, vrijgave, golden batch, CIP-reiniging, operator ondersteuning, trending, in-line metingen, productie- en technologie dashboards, monitoring van utilities, en nog veel meer.

Mis het niet en volg ons op LinkedIn: