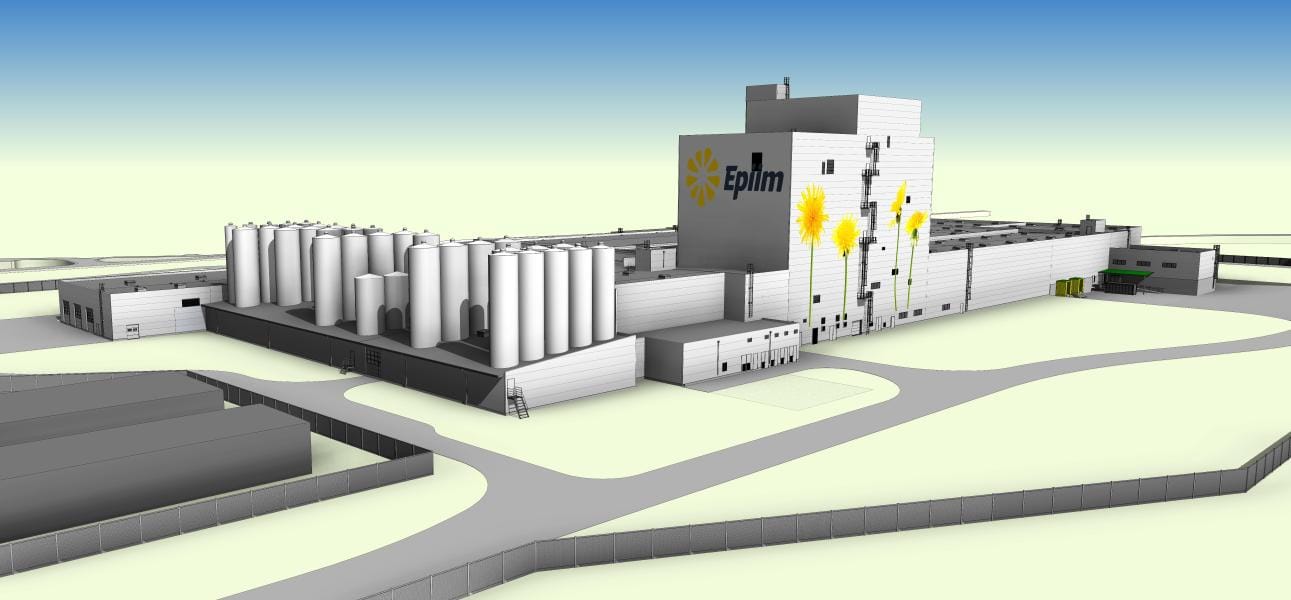

HAI customer in the picture: E-Piim’s new cheese plant in Estonia

HAI customer in the picture: E-Piim’s new cheese plant in Estonia

hai-app software plays an important role right from startup

Expertise in cheese and milk powder

Randel Veerits, Plant Director of E-Piim, explains: “There is a lot of expertise in dairy production in the Netherlands, particularly in cheese and milk powder production. That’s how we discovered that HAI’s software is used by most major dairy producers as an information system for their factories. Right from the initial contacts with HAI, we understood that they have a lot of practical experience in the dairy industry that goes beyond just implementing their own software. As a result, they have also played an important advisory role in discussions about system architecture, especially when it comes to integrating IT and OT systems. Their hands-on experience has proven very valuable, also during the startup.”

Randel Veerits, Plant Director: “We discovered that HAI’s software is used by most major dairy producers as an information system for their factories. Their hands-on experience has proven very valuable, also during the startup.”

Factory startup

So, the hai-app software is already playing a significant role in the startup and will also be crucial for the daily operation of the new factory. That’s why René Danker, HAI consultant, was asked to be personally present during the startup week to support the production team. The dynamics to prepare for startup and initial production are not new to HAI. René assisted the operators that work in the milk reception area of the factory and those who work at the cheese production lines in documenting their activities and process controls in the hai-app. He helped the quality team with the registration of product and quality controls.

HAI collaborating with Tetra Pak and Batenburg Bellt

International team

E-Piim decided to go for the best suppliers for each part of the project. Consequently, they ended up with an international team of suppliers from different countries, co-operating in this ambitious Estonian project. As a supplier of Cloud Software, HAI is used to working remotely. “However, setting up the HAI software in the context of building a new factory creates quite some extra dynamics”, says René, with a sense of understatement.“Sure it was challenging to prepare the start-up of such a big project mainly co-operating through on-line meetings. I worked closely with the local team in Estonia and suppliers from Poland, Sweden Spain and Germany. Though challenging, it was fun, and it worked out well.”

Real-time KPI dashboards

Right from the start E-Piim wants to monitor closely their factory KPI’s. HAI is now developing dashboards that show these KPI’s in real-time. These KPI’s relate amongst others to production output and effiency, product quality, energy consumption and safety.

Still much work to be done

About E-piim

Get inspired

Interested in more best practices of smart use of factory data, especially in the Food Industry?

Get inspired by successes of others when it comes to OEE, quality, positive release, golden batch, CIP-cleaning, operator support, factory data anaytics, in-line measurements, production & technology dashboards… and much more.

Don’t miss a thing, follow us on LinkedIn: