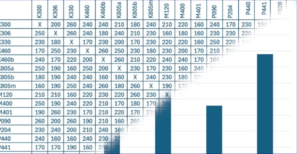

EIB-rapport: Europese industrie zet in op verduurzaming en digitalisering CONCEPT

An award winning project with successful use of Artificial Intelligence in the food industry. More and more manufacturers discover how they can improve their production processes with the smart use of factory data. A practical example aimed at improving yield and quality in the industrial production of cheese.